So my 3D printer has arrived!

But I am out of town on business...

While anxiously waiting to return and unpack it, I have started working on what will be my first project once I have my "3D Legs" under me.

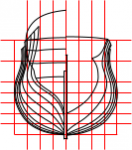

This is a vector drawing I made from an old lines drawing I had. I will import this to my 3D software and start modeling today.

Pictures of 3D printer to follow.

Reply With Quote

Reply With Quote

Bookmarks