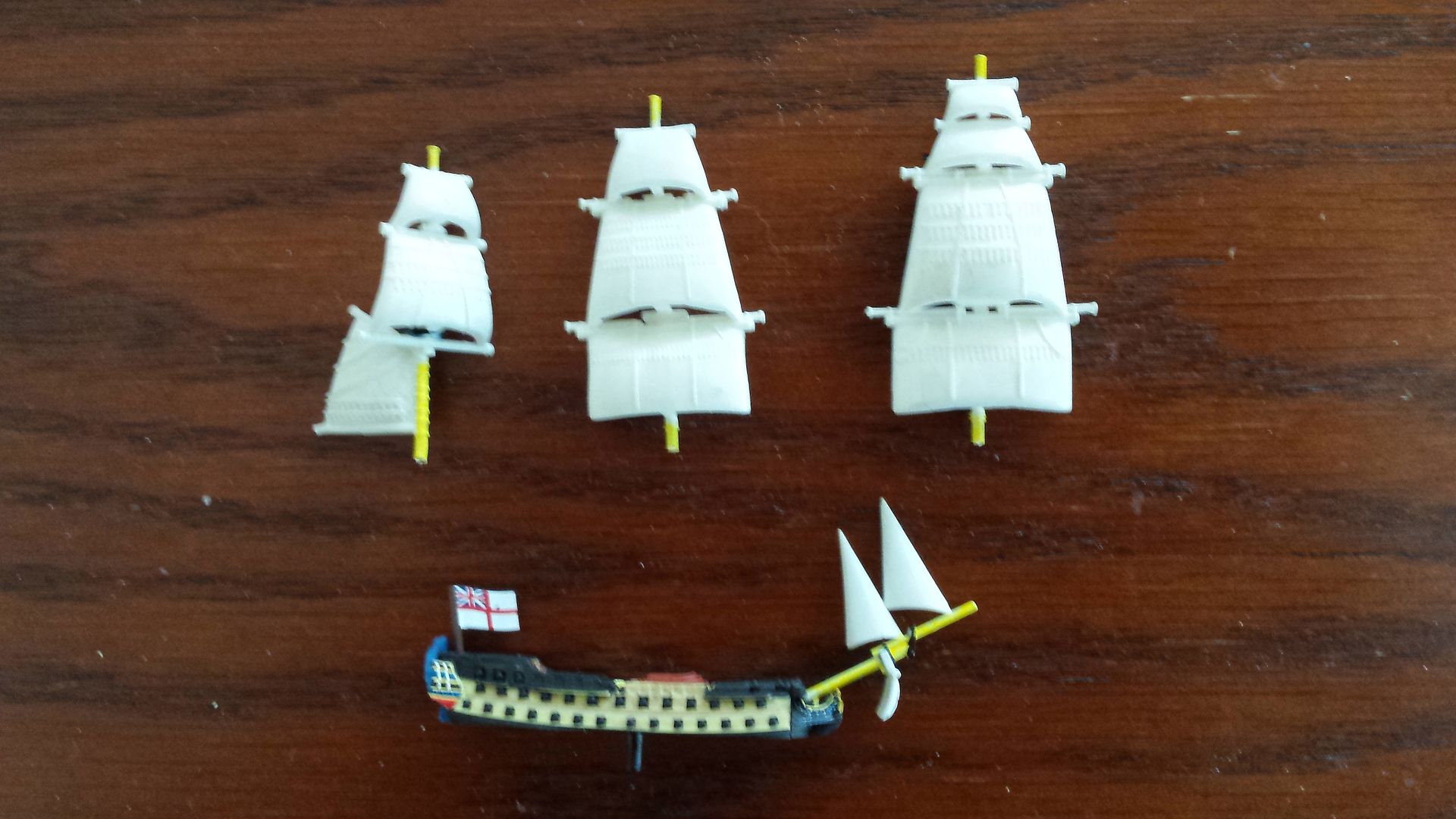

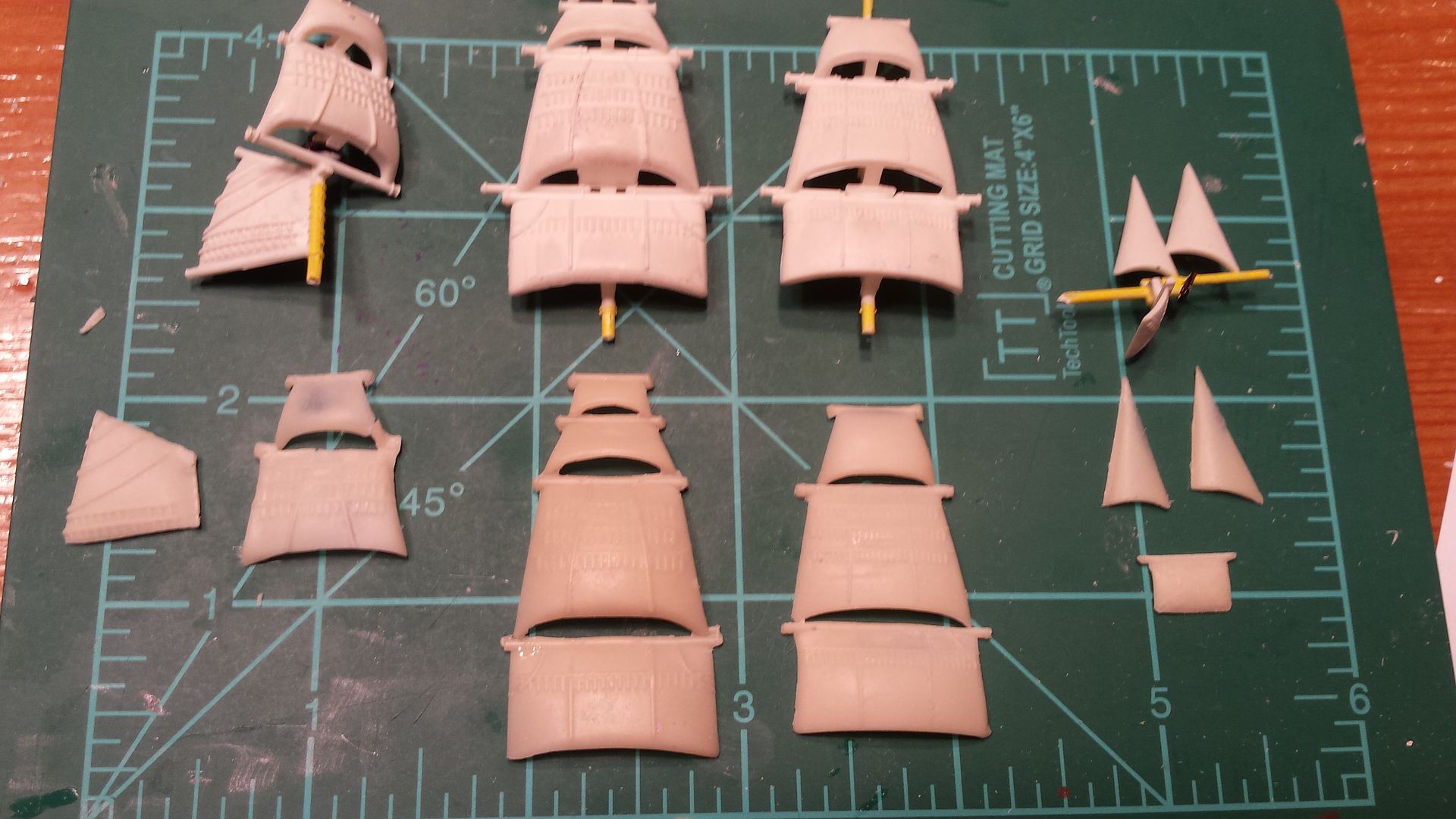

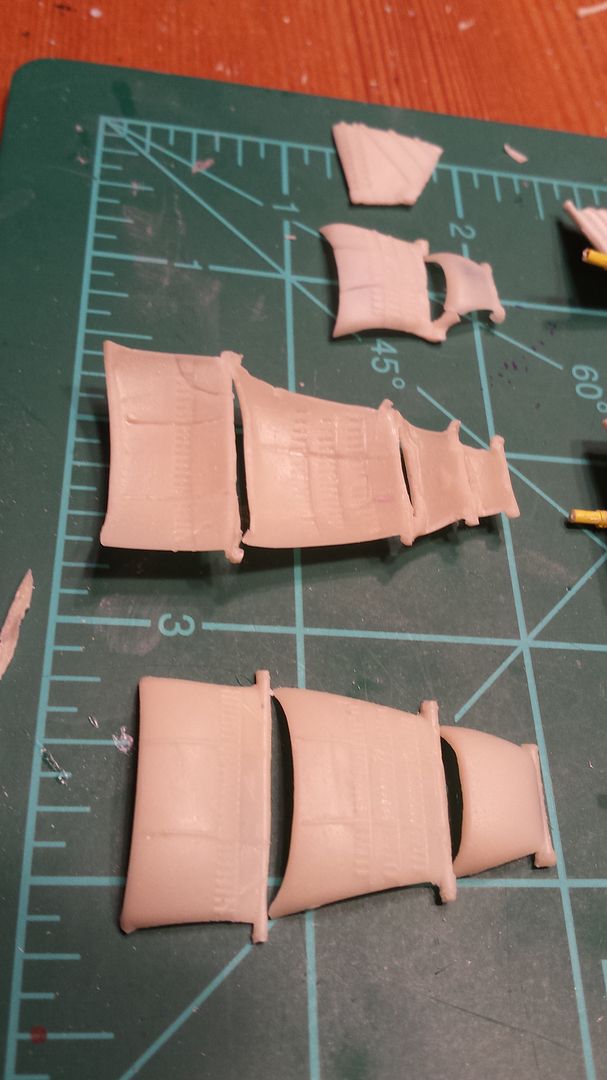

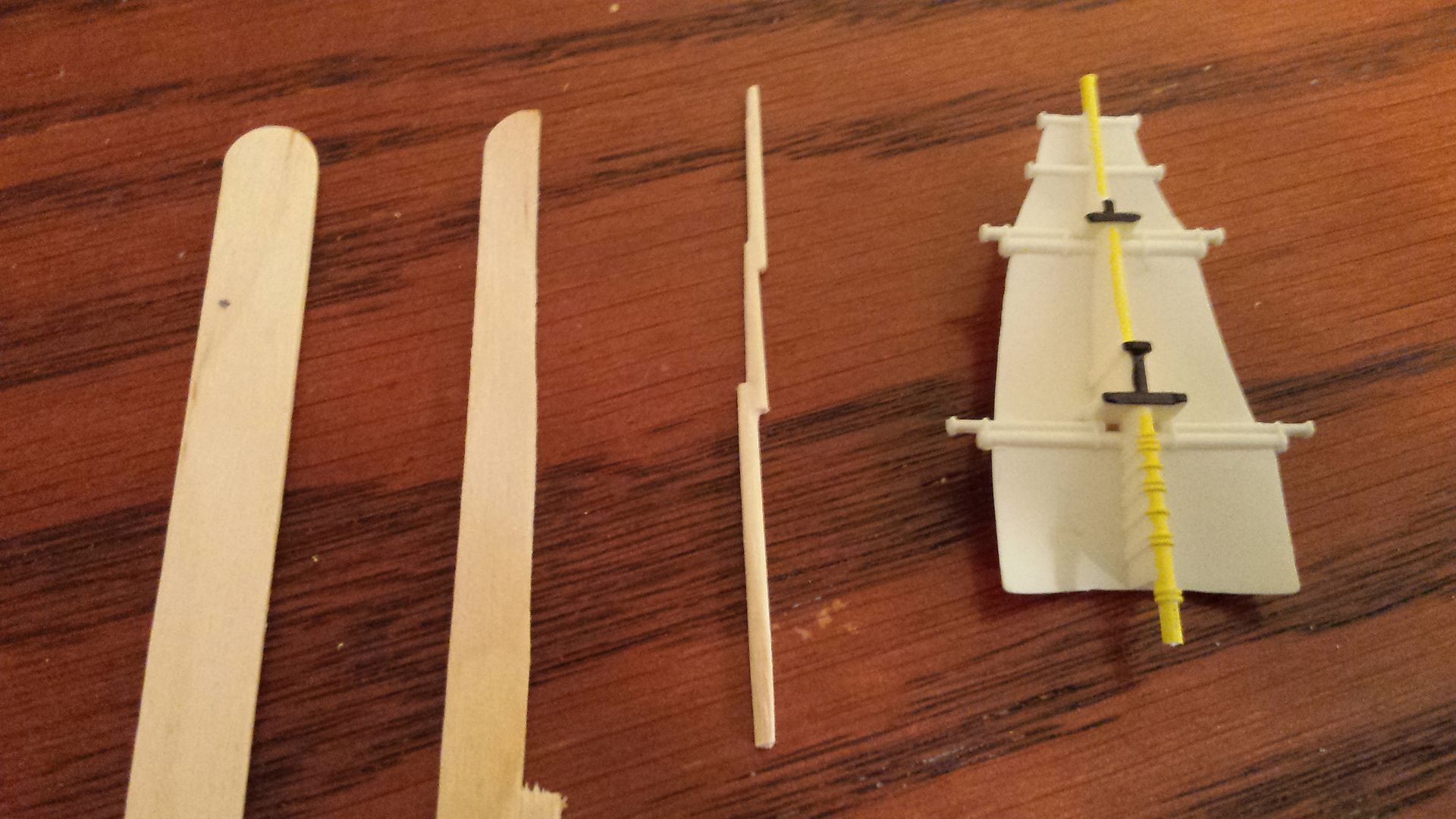

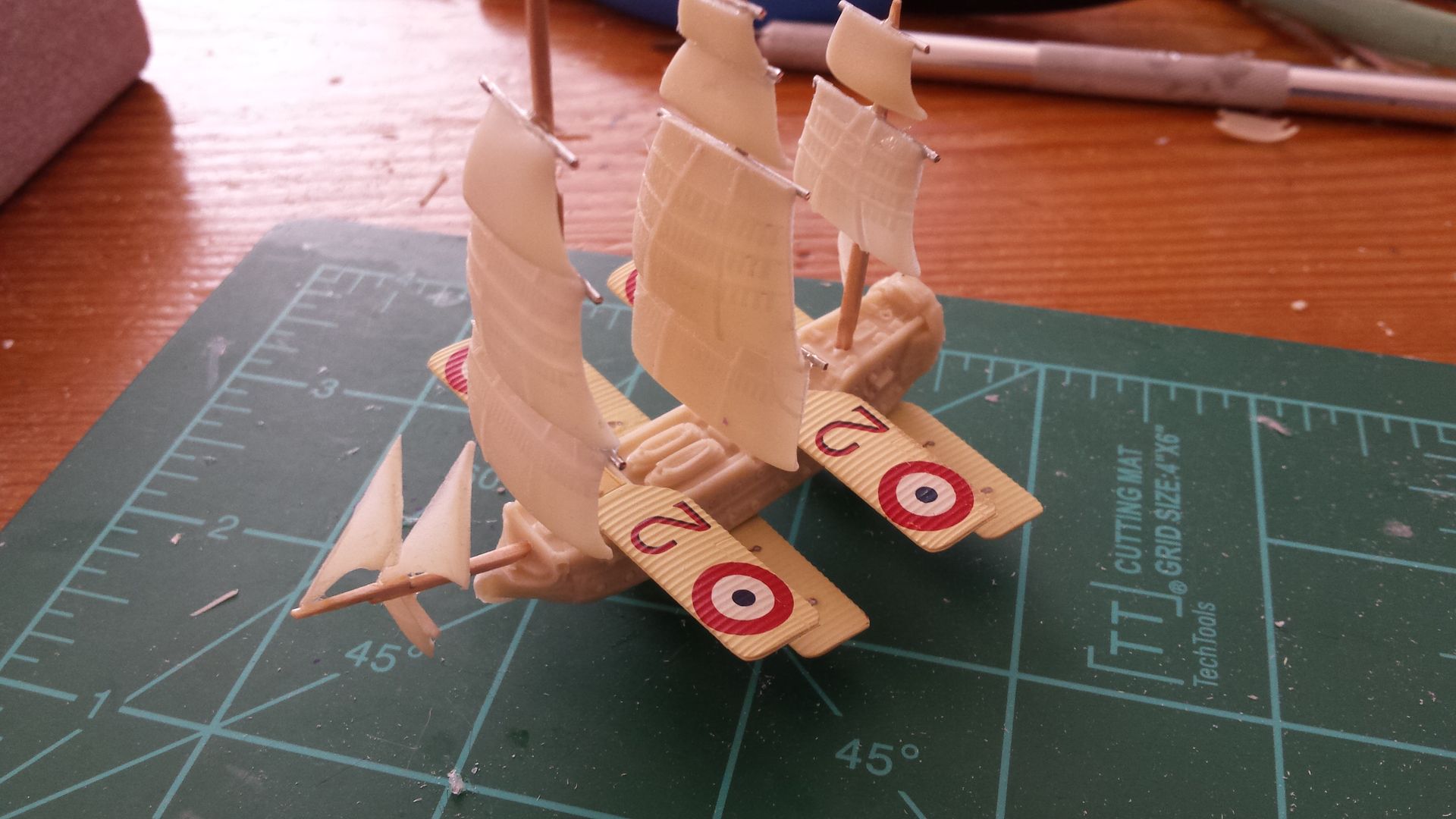

So I like the name, would you nautical knights have some ideas for me? I am looking at the Audacious as a repaint and wonder what ship we have might make the closest one to convert? Arrogant class 74 guns 3rd rate SOL 168' length, 46' beam, 28 32# on gun deck, 28 18# on upper deck, quarterdeck 14 9#, forecastle 4 9#. Just lookin' for something to re-build . . . would also appreciate ideas on the log details as well, thanks!

Reply With Quote

Reply With Quote

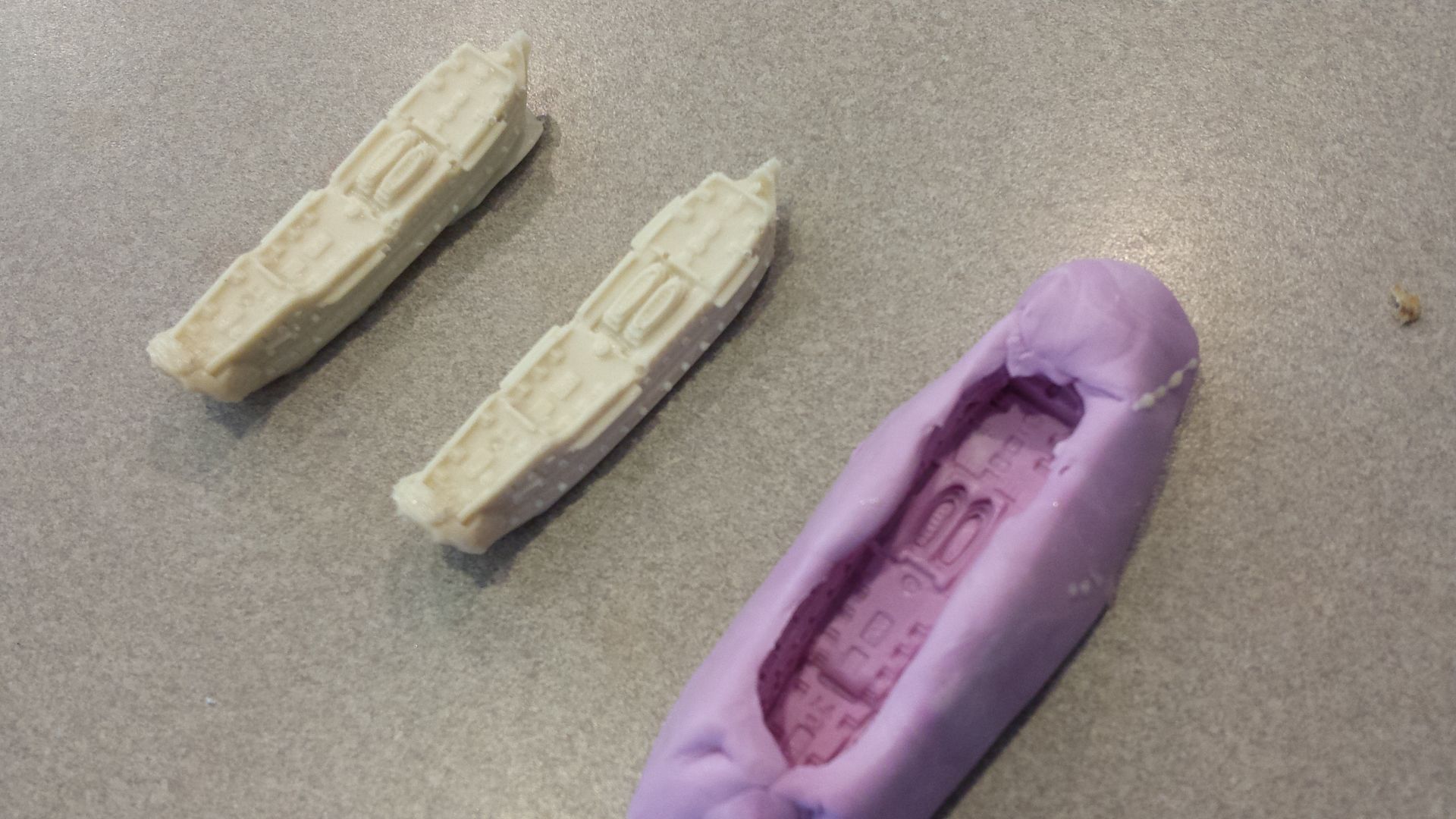

Wow very cool. Can't wait to see finished.

Wow very cool. Can't wait to see finished.

Bookmarks